.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

China supply Low price 5083 5052 3003 7075 aluminum plate sheets

Different MOQ,different price

Contact us immediately to solve your purchasing needs!

Why choose us:

1.20+ years factory

2.Free sample

3.Support OEM/ODM

4.24hours Service

|

Name |

Aluminium sheet |

Thickness |

Width |

Temper |

|

Standard |

JIS G3141,DIN1623,EN10130 |

0.2-8.0 |

20-2300 |

O,H12,H14,H16,H18,H22,H24,H26 |

|

Material |

1050,1060,3003, 3A21,5052.5005.5083.5A05,6061 |

0.2-8.0 |

20-2300 |

O,H12,H14,H16,H18,H22,H24,H26 |

|

Sheet |

0.15 mm- 2.0mm |

0.2-8.0 |

20-2300 |

O,H12,H14,H34,H32,H36,H111,H112 |

|

Normal sheet |

2.0mm-6.0mm |

0.2-8.0 |

20-2300 |

T4,T6,T651 |

|

Medium plate |

6.0 mmt-25.0mm |

0.2-8.0 |

20-2300 |

O,H12,H14,H16,H18,H22,H24,H26 |

|

Plate |

25mm-200mm |

Size can be produced as per clients requirement |

||

|

Width |

900mm-3000mm |

Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing |

||

|

Super thick plate |

more than 200mm |

Mirror,Brush,Perforated,Tread plate ,Corrugated etc |

||

|

Packing |

Export standard packing or according to customers’ requirement |

ASTM B209,EN573-1 |

||

|

Certificate |

ISO9001:2008,SGS |

1 ton |

||

|

Shipment |

Within10-15 workdays,25-30days when the quantity beyond 1000tons |

TT OR LC at sight |

||

Definition

Aluminum sheet refers to aluminum products with a thickness of more than 0.2 mm and less than 500 mm, a width of more than 200 mm, and a length of less than 16 meters. Aluminum foil is less than 0.2 mm thick, and aluminum sheet is more than 500 mm thick. Aluminum sheet is usually produced by hot rolling, cold rolling and other processes.

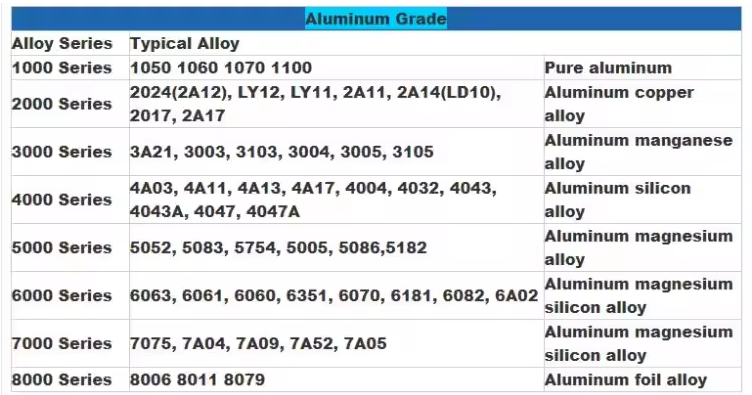

Types of aluminum plates

1.Aluminum plates can be divided into the following categories according to their composition and manufacturing process:

2.Pure aluminum plate: Made of pure aluminum as raw material, with a purity of more than 99%. Pure aluminum plate has excellent ductility and corrosion resistance, but low strength, and is mainly used in electronics, chemical industry and other fields.

3.Alloy aluminum plate: Add copper, magnesium, manganese, silicon, zinc and other elements to aluminum to form an aluminum alloy. This type of aluminum plate is both light and high-strength, and is widely used in construction, transportation, aerospace and other fields.

4.Composite aluminum plate: Made of aluminum plate and other metals or materials, such as aluminum-plastic composite plate. Composite aluminum plate combines the excellent properties of aluminum and the characteristics of other materials, and is widely used in architectural decoration and other fields

Manufacturing process of aluminum plate

The manufacturing process of aluminum plate mainly includes the following steps:

Casting: The aluminum ingot is melted and cast into a preliminary aluminum plate billet.

Hot rolling: The aluminum plate billet is heated to a high temperature and rolled into an aluminum plate of the required thickness through a rolling mill. This process can improve the strength and toughness of the aluminum plate.

Cold rolling: The hot-rolled aluminum plate is further cooled and rolled through a rolling mill again to achieve higher precision and surface finish.

Heat treatment: Through heat treatment processes such as annealing and aging, the internal structure of the aluminum plate is adjusted to improve its comprehensive performance.

Surface treatment: The aluminum plate is subjected to surface treatments such as oxidation, coating, and polishing to improve its corrosion resistance and decorative effect

Application of aluminum plates

Due to the excellent performance of aluminum plates, they have been widely used in various fields:

Construction field: aluminum plates are often used for exterior wall decoration, roofs, ceilings and other building components. Aluminum plates are lightweight and durable, and can be easily processed into various complex shapes. They are important materials for modern buildings.

Transportation field: aluminum plates are widely used in the manufacture of vehicles such as cars, trains, ships, and airplanes. The lightweight of aluminum plates helps to improve fuel efficiency and reduce energy consumption.

Aerospace: aluminum plates are particularly important in the aerospace field. Their light weight and high strength make them the main materials for aircraft fuselages, wing surfaces and other structures.

Packaging: aluminum plates are used to make packaging materials for food and medicines, such as aluminum cans and aluminum foil. Its excellent anti-corrosion properties and non-toxicity ensure the safety of packaging.

Electronic and electrical appliances: aluminum plates are also widely used in the field of electronic and electrical appliances, such as radiators and housings. The excellent thermal conductivity of aluminum plates helps to dissipate heat in electronic products.

Advantage

1.High cutting precision: complete equipment manufacturing and production, special equipment cutting neat incisions, surface treatment flat and smooth

2.Aluminum alloy material: stable raw material supplier, careful workmanship, quality assurance

3.Large amount of spot inventory: aluminum steel inventory, no need to worry about out-of-stock problems

4.Free cutting on demand: free cutting according to your needs, manufacturing aluminum plate products suitable for you

Packing

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)