square rectangular galvanized steel hollow tube price

MOQ: 10Ton/USD 480-580

Different MOQ, different prices

If you need it, please contact our customer service as soon as possible

Our Advantage

1.5000㎡super large warehouse

2.5000 ton inventory

3.Eliminate middleman price difference

4.Service attentively and solve problems quickly

Specification:

|

Application |

Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe |

|

Alloy Or Not |

Non-Alloy |

|

Section Shape |

Square |

|

Special Pipe |

Thick Wall Pipe |

|

Thickness |

0.35 - 1.5 mm, 1.0 - 35 mm |

|

Standard |

ASTM |

|

Length |

1-15 Meters, 0.5 - 30 mm, 12M, 6m, 6.4M |

|

Certificate |

ISO9001 |

|

Grade |

A |

|

Surface Treatment |

galvanized |

|

Tolerance |

±5%, ±1%, ±10% |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

Oiled or Non-oiled |

Non-oiled |

|

Invoicing |

by actual weight |

|

Delivery Time |

7-15 days |

|

Standard |

JIS |

|

Material |

Galvanized Steel |

|

Type |

Galvanized Square Tube |

|

Keyword |

Mill Test Certificate Steel Pipe |

|

Usage |

Oil Gas Sewage Transport |

|

Shape |

Round.square.Rectangle |

|

Surface |

Customers't Requirement |

|

Model Number |

PBB: 0032 |

|

Length |

12M, 6m, 6.4M |

The steel pipe production line with an annual output of 700,000 tons, has a CNAS certification laboratory, adopts advanced American GBNB and electrical control systems from the German brain. And cooperate with many large steel plate factories to re-inspect raw materials. The zinc coating ranges from 40-220 g/m², the surface is passivated and can be oiled, and the pipe section can be processed into bevels, threads, and grooves. In addition, the company has also introduced a slitting machine to meet the different requirements of customers for products

|

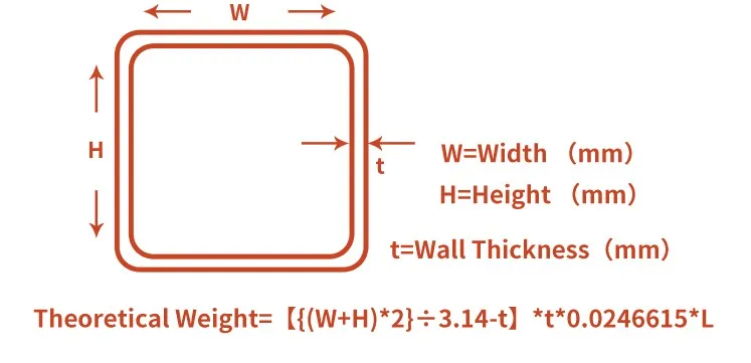

Square and Rectangular Steel Pipe size chart |

||

|

Square Hollow Section |

Rectangular Hollow Section |

Thickness(mm) |

|

20*20 25*25 30*30 |

20*40 30*40 |

1.2-3.0 |

|

40*40 50*50 |

30*50 25*50 30*60 40*60 |

1.2-4.75 |

|

60*60 |

50*70 40*80 |

1.2-5.75 |

|

70*70 80*80 75*75 90*90 100*100 |

60*80 50*80 100*40 120*80 |

1.5-5.75 |

|

120*120 140*140 150*150 |

160*80 100*150 140*80 100*180 200*100 |

2.5-10.0 |

|

160*160 180*180 200*200 |

200*150 250*150 |

3.5-12.0 |

|

250*250 300*300 400*200 350*350 350*300 |

250*200 300*200 350*200 350*250 450*250 400*300 500*200 |

4.5-15.75 |

|

400*400 280*280 450*300 450*200 |

400*350 400*250 500*250 500*300 400*600 |

5.0-20.0 |

Strict Quality Control

(1) During and after production, 4 QC personnel with more than 5 years of experience randomly inspect the products. (2) National accredited laboratory with CNAS certificate (3) Accept inspection from a third party designated/paid by the buyer, such as SGS, BV. (4) Recognized by customers in Malaysia, Indonesia, Singapore, the Philippines, Australia, Peru and the United Kingdom. We have UL, ISO9001/18001, FPC certificates.

(5)Inspection: Tensile test, yield test, flattening test, bending test, chemical composition, etc.

Square Steel Tube

Black-coated steel pipe features an all-over black finish. Due to its high heat resistance, black-coated steel pipes are commonly used in fire sprinkler systems. Black steel pipe is also popular for other water transfer applications, including potable water and gas lines.

Depending on the desired outcome or performance required, galvanization can occur in various ways, including hot-dip galvanization, electroplating, mechanical plating, and plastic coating. Each galvanization process provides unique advantages, delivering results that match your specification requirements.窗体底端

Black-coated steel pipe features an all-over black finish. Due to its high heat resistance, black-coated steel pipes are commonly used in fire sprinkler systems. Black steel pipe is also popular for other water transfer applications, including potable water and gas lines.

Depending on the desired outcome or performance required, galvanization can occur in various ways, including hot-dip galvanization, electroplating, mechanical plating, and plastic coating. Each galvanization process provides unique advantages, delivering results that match your specification requirements.

Square Steel Tubing Applications

Structural steel square tubing is a versatile material suitable for various applications due to its ability to be utilized in both static and dynamic scenarios. Its precise dimensions, smooth surface, and strong composition make it well-suited for a diverse array of uses, such as trailer beds, bridges, buildings, highways, machine parts, frames, and structural components.

What Is the Difference Between ASTM Hot Rolled & Cold Rolled Steel Tubing?

Hot rolled steel is a mill process that takes place at high temperatures, above 1,700°F, allowing the steel to be molded and shaped into larger sizes without difficulty. This process is more cost-effective than cold rolling, as it eliminates the need for additional manufacturing steps. In contrast, cold rolling is used to decrease the thickness of plate and sheet metal by introducing defects into the crystal structure, which increases the metal's yield strength and hardness.

Where are galvanized steel rectangular pipes used?

Our galvanized steel rectangular pipes are utilized across various commercial industries, whether it be in residential settings, apartments, or even gardens belonging to neighbors. The stability of galvanized rectangular steel stems from its specific shape, making it a contemporary and adaptable structural component suitable for a wide range of applications, both professional and recreational, indoors and outdoors. Examples include its use in stands, exhibition structures, balustrades for balconies, terraces, and stairs, as well as in the construction of tables, shelves, benches, furniture, machinery, and equipment frameworks.

Packing & Shipping

|

Packing |

1.Inner Packing:Each bundle is equipped with two nylon slings. |

|

2.Outer Packing:Wrapped with waterproof colth. |

|

|

3.We also can do as customers' requirements. |

|

|

Shipping |

1.Shipping by containers |

|

2.Shipping by bulk ship. |